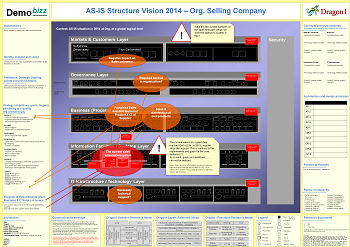

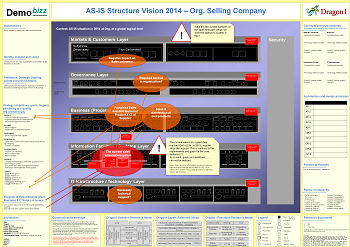

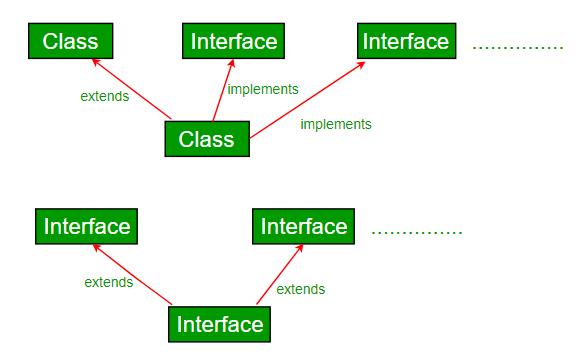

maintaining standards at every stage of the process and performing quick checks of the work whenever necessary. To maintain industrial stands of workflow with technical aspects. Adopting new technics and applying them in suitable designing concepts.You must conduct monitoring checks to determine whether other teams adhere to the design and parameters correctly.Maintain overall quality and measurement standards.Understanding the technical aspect of the component.You can make technical changes in the design based on customer feedback before commencing the actual work in the real world. A soft copy of the work containing the details of Height, Width, and a few more component measurements will be specified.ĭesigns and work concepts can be visually represented in 2D, which is a cost-effective approach. It helps determine the design and technical details of the project. Layouts, floor plans, electrical wiring plans, plumbing line pans, and much more construction, HVAC, and engineering professionals use blueprints for their work daily.

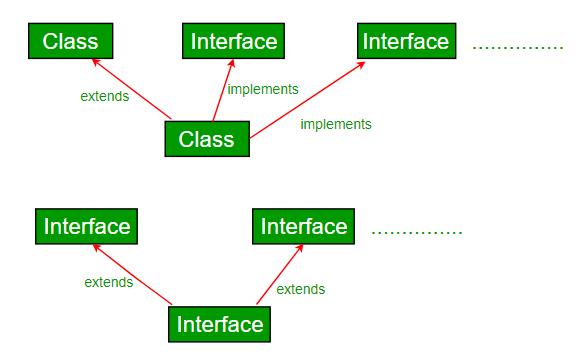

Our technical knowledge of designs and assemblies is improved as a result. It is quick and easy it takes only to study and understand the design and follow the working procedure per design standards and approvals.

Reduce, educate, and maintain standards of process flow with Universal standards. Explain the design with conceptual and technical understanding, which is interesting and encouraged by clients. You can identify errors in the process as early as possible. Work status and its effectiveness of completion rate. The material used for the components in the design and cost. It is used for understanding the design of the product. Many more MNCs have blueprint design teams for projects like LNT, Wipro, Cyient, Tech Mahindra spaces, etc. To know the project status and estimate the completion rate.Įvery company will have and follow this making for multiple reasons like an interior, exterior, complete house, mechanical, technical blueprints for components, electrical wiring related blueprint, civil constructions, and many more. You can check the work completion rate by using checklists and refer to a blueprint at any stage of the project. Technical details are already clearly given with the design so blueprint workers can quickly look at the design and maintain the parameter standards as required in case of any ambiguous situations. The finalized design budget of the project gets finalized by considering all constraints such as material, labor, and other effective costs. Design costs less, and one of the blueprint designs gets finalized out of multiple designees. Delivering the product to the client as planned and approved using this. Maintain the standards in a workflow from start to end. Understanding the assembling and design of components. Understand the material used and analyze its suitability for a working environment. Secondly, understand the universal standards of measurement used for design, ex:- meters, Feet, inches, centimeters, etc. First, you need to know what the design is made of or the purpose of the design. The study is very interesting there is a step-by-step process to understand it. Drawbacks of the design can be identified and improved instantly. It can be used to understand and explain the detailed work plan with the help of design mode.

It’s a softcopy of imagining the values of the project. We communicate, understand specifications, and design the blueprint. It is a design or a technical drawing that explains the overall details of the component.

0 kommentar(er)

0 kommentar(er)